NanoDiamond-graphene filler in Heat Conductivity of Epoxy Resin

Some time ago, South Korean researchers designed a new type of nanocomposite material: the use of nanodiamond (nanodiamond, ND) hybrid graphene (graphene nanoplatelets, GNPs) to prepare nanocomposite materials (ND@GNPs), with this kind of filler Toughening the epoxy resin (EP) matrix to prepare thermoset composite materials with stable physical properties and excellent thermal conductivity, which can be used in the electronics and automotive industries.

The thermal conductivity of polymer-based materials is the key to its application expansion. The research results show that the addition of ceramic particle fillers such as boron nitride, silicon carbide, and alumina greatly improves the thermal conductivity of the composite material, but the performance of this carbon-based filler is better. Nano-diamond can enhance heat transfer and heat dissipation, and can also increase interface interaction and improve the thermophysical properties of composite materials.

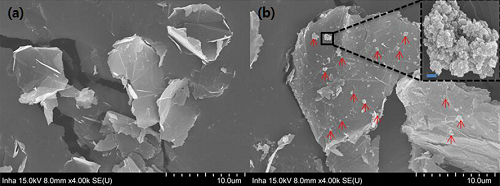

Through experiments, the team selected nanodiamonds with a particle size of less than 1μm and graphene nanosheets with a thickness of less than 100nm for hybridization, and then dispersed the composite material in an epoxy resin matrix at 20 wt% (mass concentration), which improved the thermal conductivity 1231%. No separated nano-diamond nano-clusters were detected on the thermally conductive adhesive, indicating that the nano-diamond nano-clusters and GNPs have a strong binding force.

The paper was published on nature with the title “Implication of thermally conductive nanodiamond-interspersed graphite nanoplatelet hybrids in thermoset composites with superior thermal management capability”.

Diamond nanoparticles, size <10nm, 99%+, Spherical. Contact us for initial test.